LA-6000 High-Speed Variable-Height Label Printer Applicator

Using the tamp-blow method, the LA-6000 can print and apply up to 40 labels per minute (dispensing output depends on label size, text change and dispensing stroke) to products that vary in height up to 19.68” (500mm). And label placement accuracy is ±0.03” (1mm).

Using the tamp-blow method, the LA-6000 can print and apply up to 40 labels per minute (dispensing output depends on label size, text change and dispensing stroke) to products that vary in height up to 19.68” (500mm). And label placement accuracy is ±0.03” (1mm).

• Interchangeable dispensing heads allow the use of different label sizes.

• Print engines by leading manufacturers such as Zebra and SATO allows an optimal match to the application and its specific printing requirements. (Thermal-transfer or direct-thermal.)

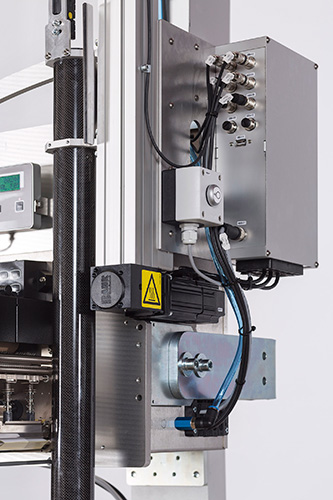

• Peak performances is achieved using a servo motor driven dispensing applicator and carbon fiber construction.

• The LA-6000 will handle large label rolls with an ergonomically adjustable reel holder taking maximum roll size of up to 13.7” (350mm) in diameter.

A sensor initially determines the height of the approaching product for labelling and then the applicator moves to the correct position at high speed. This reduces the travelling distance for label application, allowing theLA-6000 to simultaneously label more accurately and up to 50 percent faster than a label printer-applicator with a pneumatically driven cylinder.

The newly redesigned microprocessor controller is compact and facilitates easy integration into existing operating environments. The system’s modular construction allows easy access to components for servicing and or maintenance, enabling convenient changing of labels and ribbons as well as easy cleaning of the print module’s thermal print head.

Special Features & Options

The LA-6000 variable-height tamp-blow print-apply system includes a number of noteworthy features that add to the operational versatility of this printer-applicator.

• Tamp-blow application. This is a very popular method of air-assisted label placement used with standard applications, and is particularly useful in the labeling of recessed areas. A printed label is fed onto a tamp pad and held by vacuum, a servo-powered cylinder extends to within .25 inch of the product, and the label is blown onto its surface to a placement accuracy of 0.03".

• One-to-one media consumption. Special label unwind and rewind dimensions are matched to the system's ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers.

• Numerous I/O's. The system can be interfaced with many types of external devices.

• Print job storage. Multiple label printing formats can be stored in the system's memory, making it easier for an operator to select a job directly from the applicator instead of downloading a computer file.

Distribution centers need to label variable sized cartons at ever increasing line speeds with accurate shipping information. And they need that labeling system to be reliable and cost-effective.

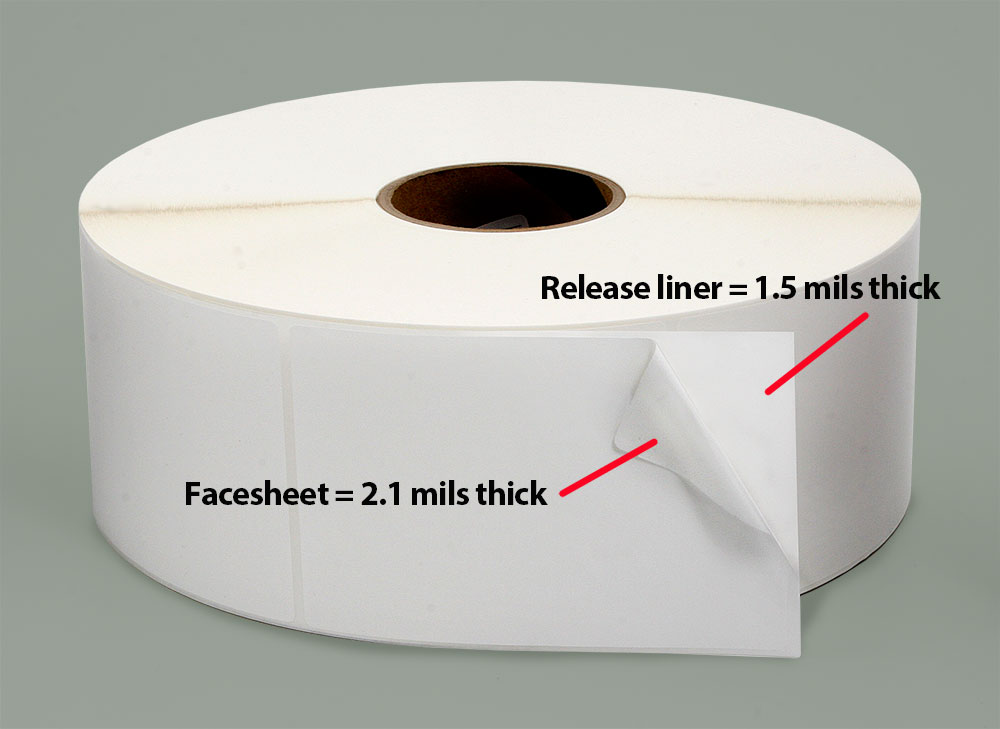

Distribution centers need to label variable sized cartons at ever increasing line speeds with accurate shipping information. And they need that labeling system to be reliable and cost-effective. The release liner is just 1.5 mils thick but also retains the strength needed for the tension of the rewind reel. Transthin 400 uses a versatile acrylic emulsion adhesive that is well suited for corrugated and plastic packaging.

The release liner is just 1.5 mils thick but also retains the strength needed for the tension of the rewind reel. Transthin 400 uses a versatile acrylic emulsion adhesive that is well suited for corrugated and plastic packaging.