Weber is applying its expertise as a leading manufacturer and supplier of pressure-sensitive labels to provide the finest in RFID smart labels.

Weber is applying its expertise as a leading manufacturer and supplier of pressure-sensitive labels to provide the finest in RFID smart labels.

Many big-box storesare now mandating RFID labels at product and carton levels for incoming products they warehouse and sell.

An RFID labeling program can not only help you meet these requirements, but also improve your logistics operations. By adding RFID tags and labels to your products or in-house processes, you can get a better handle on where your products are at any given time.

Weber can supply the custom RFID labels you need to fit your products and help you with equipment to apply those labels. We can even help you print/encode/apply labels if you need variable data on the labels with our label printer applicators.

When working with RFID labels, specifically Walmart, you need to get actual samples of the label you will be using and get them qualified by their source. Our experts can help you get the samples and quote your needs so you can anticipate timing and costs. Let us know what you need and we can help. We can just build your labels or print and encode them so they are ready for application.

Have you read our RFID Basics 101 blog for an overview of RFID labeling?

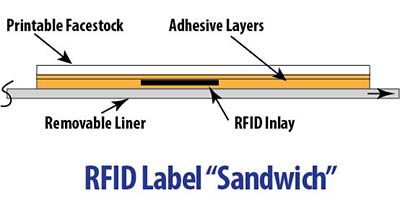

All SmartTrak RFID labels are produced using fully tested RFID inlays from trusted sources like Avery Dennison and Alien Technology. Every label is certified to be the highest in quality.

All SmartTrak RFID labels are produced using fully tested RFID inlays from trusted sources like Avery Dennison and Alien Technology. Every label is certified to be the highest in quality.